The Future of US Manufacturing: Challenges and Opportunities

The Future of US Manufacturing: What Are the Key Challenges and Opportunities? involves navigating technological advancements, supply chain resilience, workforce development, and sustainability while capitalizing on reshoring trends and innovation to maintain global competitiveness.

The landscape of American manufacturing is at a pivotal moment. As we look to The Future of US Manufacturing: What Are the Key Challenges and Opportunities?, it’s crucial to understand the forces shaping its trajectory. What hurdles must be overcome, and what promising avenues lie ahead?

The Evolving Landscape of US Manufacturing

US manufacturing has long been a cornerstone of the nation’s economy, but its role is constantly evolving. Shifts in technology, global economics, and consumer demand are reshaping the industry, presenting both challenges and opportunities for manufacturers across the country.

Understanding these changes is vital for businesses looking to thrive in the years to come. What are the key trends influencing the future of US manufacturing, and how can companies adapt to stay competitive?

Technological Advancements in Manufacturing

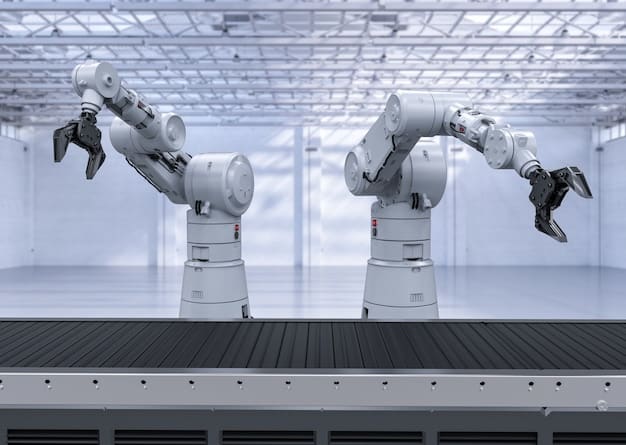

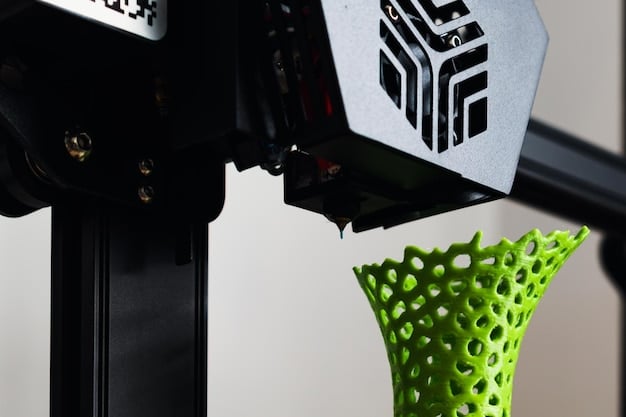

The integration of advanced technologies such as artificial intelligence (AI), robotics, and 3D printing is revolutionizing manufacturing processes. These innovations are increasing efficiency, reducing costs, and enabling the production of more complex and customized products.

Globalization and Trade Dynamics

The globalized economy has created intricate supply chains and trade relationships. Understanding these dynamics and adapting to changes in trade policies are critical for US manufacturers seeking to expand their reach and remain competitive on a global scale.

Here are some areas where manufacturers need to pay attention regarding challenges and opportunities:

- Cybersecurity Threats: Manufacturers must fortify their digital defenses to protect sensitive data and prevent disruptions to operations.

- Data Analytics for Optimization: Leveraging data analytics to optimize production processes, improve quality control, and enhance decision-making is becoming essential.

- Supply Chain Disruptions: Building resilience into supply chains to mitigate the impact of disruptions caused by geopolitical events, natural disasters, or other unforeseen circumstances is a top priority.

In conclusion, the US manufacturing sector is undergoing a period of significant transformation, driven by technological advancements and globalization. By embracing innovation and adapting to changing market conditions, US manufacturers can position themselves for success in the future.

Workforce Development and Skills Gap

One of the most pressing challenges facing US manufacturing is the shortage of skilled workers. As technology evolves, the skills required to operate and maintain advanced manufacturing equipment are becoming increasingly specialized, leading to a growing skills gap.

Addressing this gap is essential for ensuring the long-term competitiveness of the US manufacturing industry. How can manufacturers attract, train, and retain the talent they need to succeed?

Strategies for Attracting Talent

Manufacturers need to implement innovative strategies to attract the next generation of workers. This includes improving the image of manufacturing careers, offering competitive wages and benefits, and creating opportunities for professional development and advancement.

Investing in Training Programs

Investing in training programs is crucial for equipping workers with the skills they need to succeed in modern manufacturing environments. Apprenticeships, on-the-job training, and partnerships with educational institutions can help bridge the skills gap and ensure a steady supply of qualified workers.

Workforce-related challenges and opportunities highlight the need for:

- STEM Education Initiatives: Supporting STEM (science, technology, engineering, and mathematics) education initiatives at the K-12 level can help cultivate an interest in manufacturing careers among young people.

- Upskilling and Reskilling Programs: Providing opportunities for existing workers to upgrade their skills and learn new technologies can help them adapt to changing job requirements.

- Collaboration with Community Colleges: Partnering with community colleges to develop customized training programs that meet the specific needs of local manufacturers can be an effective way to address the skills gap.

In summary, workforce development is a critical issue for the future of US manufacturing. By investing in training programs and implementing strategies to attract and retain talent, manufacturers can overcome the skills gap and build a strong and competitive workforce.

Supply Chain Resilience and Localization

The COVID-19 pandemic exposed vulnerabilities in global supply chains, highlighting the need for greater resilience and localization. Many US manufacturers are now reevaluating their supply chain strategies to reduce their reliance on overseas suppliers and mitigate the risk of disruptions.

Building more resilient and localized supply chains can help manufacturers improve their agility, responsiveness, and competitiveness. What steps can companies take to strengthen their supply chains and reduce their exposure to disruptions?

Diversifying Supply Sources

Diversifying supply sources is a key strategy for reducing reliance on any single supplier or region. By establishing relationships with multiple suppliers, manufacturers can mitigate the impact of disruptions caused by natural disasters, political instability, or other unforeseen events.

Investing in Domestic Sourcing

Increasingly, manufacturers are looking to source more components and materials from domestic suppliers. This can help reduce transportation costs, improve lead times, and support local economies.

To build more robust supply chains, manufacturers may want to consider:

- Nearshoring Opportunities: Exploring nearshoring opportunities in countries closer to the US can provide a balance between cost competitiveness and supply chain resilience.

- Advanced Inventory Management: Implementing advanced inventory management techniques, such as predictive analytics, can help manufacturers optimize inventory levels and reduce the risk of stockouts.

- Collaboration with Suppliers: Building strong relationships with key suppliers and collaborating on supply chain planning can improve visibility and coordination, leading to more resilient supply chains.

In short, supply chain resilience is a critical factor in the future of US manufacturing. By diversifying supply sources, investing in domestic sourcing, and building strong relationships with suppliers, manufacturers can create more robust and agile supply chains that are better able to withstand disruptions.

Sustainability and Green Manufacturing

Sustainability is becoming an increasingly important consideration for manufacturers. Consumers are demanding more environmentally friendly products, and governments are enacting stricter regulations to reduce carbon emissions and promote sustainable practices.

Manufacturers that embrace sustainability and green manufacturing principles can not only reduce their environmental impact but also improve their competitiveness and attract environmentally conscious customers. How can companies integrate sustainability into their manufacturing operations?

Implementing Energy-Efficient Technologies

Investing in energy-efficient technologies, such as LED lighting, variable speed drives, and advanced insulation, can significantly reduce energy consumption and lower operating costs. Manufacturers can also explore renewable energy sources, such as solar and wind power, to further reduce their carbon footprint.

Reducing Waste and Pollution

Implementing waste reduction programs and pollution prevention measures can help manufacturers minimize their environmental impact and comply with environmental regulations. This includes recycling materials, reducing water consumption, and preventing air and water pollution.

Opportunities for sustainability in manufacturing involve many options and choices. Some of which may include:

- Life Cycle Assessment: Conducting life cycle assessments to evaluate the environmental impact of products and processes can help manufacturers identify opportunities for improvement.

- Circular Economy Principles: Adopting circular economy principles, such as designing products for disassembly and reuse, can reduce waste and conserve resources.

- Sustainable Materials: Sourcing sustainable materials, such as recycled plastics and bio-based materials, can help manufacturers reduce their environmental footprint and meet customer demand for eco-friendly products.

In conclusion, sustainability is a key driver of innovation and competitiveness in the future of US manufacturing. By implementing energy-efficient technologies, reducing waste and pollution, and adopting sustainable materials, manufacturers can create more environmentally friendly products and processes that benefit both their bottom line and the planet.

The Role of Government and Policy

Government policies and regulations play a significant role in shaping the future of US manufacturing. Tax incentives, trade policies, and regulatory frameworks can all have a significant impact on the competitiveness of US manufacturers.

Manufacturers need to stay informed about government policies and advocate for policies that support innovation, investment, and job creation. What are some of the key policy issues affecting US manufacturing?

Tax Reform and Incentives

Tax reform can provide incentives for manufacturers to invest in new equipment, expand their operations, and create jobs. Tax credits for research and development, investment in renewable energy, and job creation can all help stimulate manufacturing activity.

Trade Agreements and Tariffs

Trade agreements and tariffs can have a significant impact on the ability of US manufacturers to compete in global markets. Negotiating fair trade agreements that level theplaying field and reducing tariffs on imported materials and components can help boost US manufacturing exports.

Here are some other factors that need to be considered when thinking about the goverment’s impact:

- Regulatory Reform: Streamlining regulations and reducing the regulatory burden on manufacturers can help lower costs and improve competitiveness.

- Infrastructure Investment: Investing in infrastructure, such as roads, bridges, and ports, can improve transportation efficiency and lower logistics costs for manufacturers.

- Workforce Development Programs: Supporting workforce development programs that provide training and education to workers can help address the skills gap and ensure a steady supply of qualified labor.

In short, government policies and regulations play a crucial role in shaping the future of US manufacturing. By advocating for policies that support innovation, investment, and job creation, manufacturers can help create a more favorable business environment and ensure the long-term competitiveness of the US manufacturing sector.

Reshoring and the Future of Domestic Production

The trend of reshoring, or bringing manufacturing operations back to the US from overseas, is gaining momentum. Rising labor costs in some countries, concerns about supply chain resilience, and government incentives are all contributing to this trend.

Reshoring can create new jobs, boost economic growth, and strengthen the US manufacturing base. How can companies capitalize on the reshoring trend and bring more production back to the United States?

Evaluating the Total Cost of Ownership

When considering reshoring, companies need to evaluate the total cost of ownership, which includes not only labor costs but also transportation costs, inventory costs, quality control costs, and intellectual property risks. In some cases, the total cost of ownership may be lower in the US than in overseas locations.

Leveraging Automation and Technology

Investing in automation and technology can help manufacturers reduce labor costs and improve productivity, making reshoring more economically viable. Advanced robotics, AI-powered manufacturing systems, and 3D printing can all help manufacturers compete with low-cost labor in other countries.

Here are some additional suggestions about capitalizing on reshoring trends:

- Government Incentives: Taking advantage of government incentives, such as tax credits and grants, can help offset the upfront costs of reshoring.

- Building a Skilled Workforce: Investing in training programs and apprenticeships can ensure that companies have access to a skilled workforce to support their reshoring efforts.

- Collaboration with Suppliers: Working closely with suppliers to establish domestic supply chains can help reduce transportation costs and improve supply chain resilience.

In conclusion, reshoring presents a significant opportunity for the future of US manufacturing. By evaluating the total cost of ownership, leveraging automation and technology, and taking advantage of government incentives, companies can bring more production back to the United States, create jobs, and boost economic growth.

| Key Point | Brief Description |

|---|---|

| 🏭 Tech Integration | Adopting AI, robotics to boost efficiency. |

| 👨💼 Skill Gap | Addressing the shortage of skilled workers. |

| ♻️ Sustainability | Focusing on green practices for a better future. |

| 🌎 Supply Chains | Ensuring resilience through diversification. |

FAQ Section

▼

The primary challenges include workforce shortages, supply chain vulnerabilities, and the need for greater sustainability. Adapting to rapid technological changes is also a key concern.

▼

Manufacturers can invest in training programs, partner with educational institutions, and offer apprenticeships to equip workers with the skills needed for modern manufacturing jobs.

▼

Reshoring can help create new jobs, boost economic growth, and strengthen the US manufacturing base by bringing production back to the United States.

▼

Manufacturers can implement energy-efficient technologies, reduce waste and pollution, adopt circular economy principles, and source sustainable materials to minimize their environmental impact.

▼

Tax incentives, fair trade agreements, regulatory reform, and infrastructure investments can all help create a more favorable business environment for US manufacturers.

Conclusion

The future of US manufacturing is bright, but success will depend on embracing innovation, addressing workforce challenges, building resilient supply chains, and prioritizing sustainability. By proactively tackling these issues, US manufacturers can position themselves for long-term growth and competitiveness in the global economy.